Don’t Overlook Apparatus Valves

Apparatus valves are easily overlooked, but their importance becomes clear when one fails. Manual valves are tucked away behind panels, while electric valves have a reputation for unreliability based on outdated technology. However, valve technology has advanced significantly, and understanding the specifics of the valves in your apparatus can contribute to safer, more efficient operations.

Electric Valves

Elkhart E14X

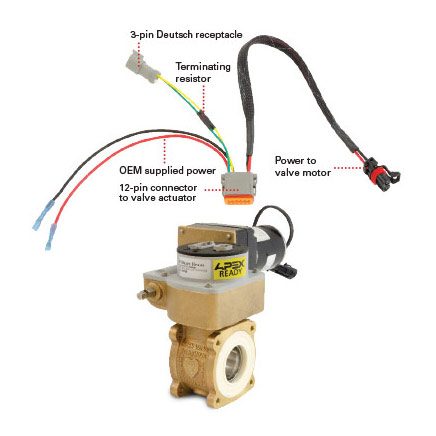

The E14X electric valve actuator interfaces with the valve to open, close, and throttle. The fully sealed design can handle continuous duty cycles and high torque requirements.

Competitor Comparisons:

Akron Navigator / Navigator Pro

Apex-S[sm mark=”tm”]

Typically used for “Tank to Pump” or “Tank Refill”, the APEX-S is a compact valve controller with no digital display.

Competitor Comparisons:

Akron Mini Navigator Pro 9327

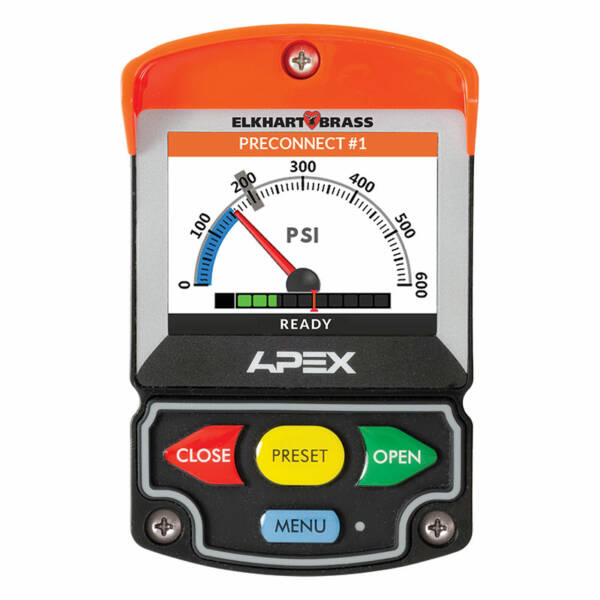

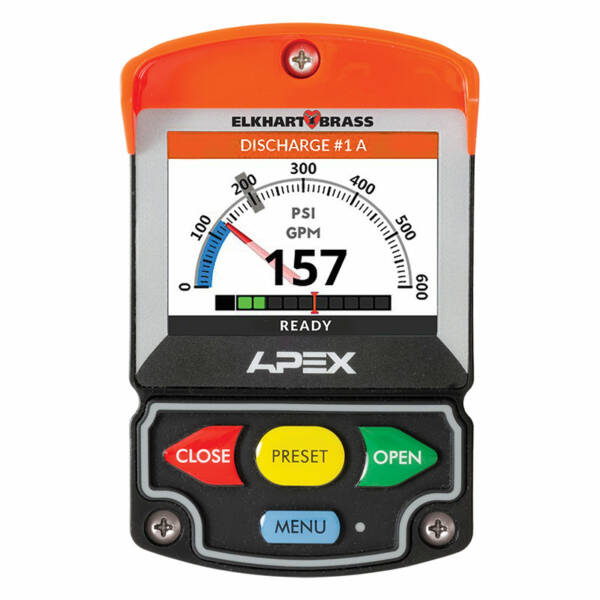

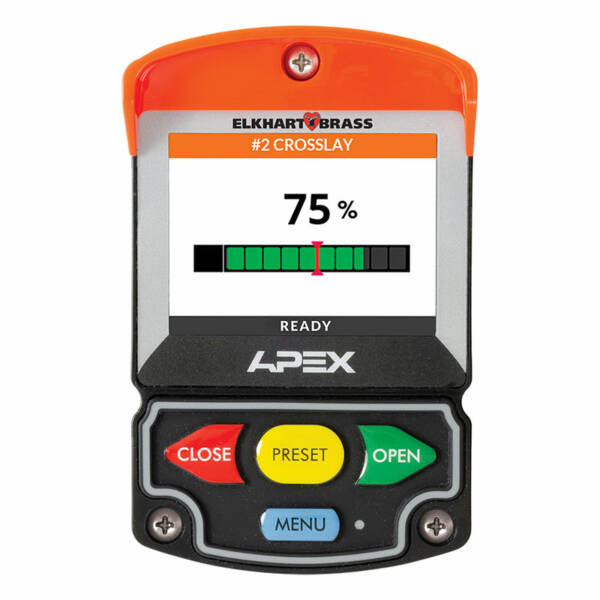

Apex-100[sm mark=”tm”]

Same functionality as the APEX-S, however, features like an LCD display and custom colors / verbiage take it a step further.

Competitor Comparisons:

Akron Navigator Pro 9333

Industry Best Warranty

The APEX controller, E14X Actuator, and Unibody Valve are all backed by an industry exclusive 10-year warranty. The 10-year warranty covers the valve, motor, and electronics. Nobody else covers the entire system like Elkhart Brass.